Industrial Spark Plugs play a crucial role in various industries. They ensure efficient performance in engines and heavy machinery. Understanding their functions can help optimize equipment.

Selecting the right spark plug isn't always straightforward. There are many options available, each designed for specific applications. Many users overlook critical features, resulting in performance issues.

In this article, we will discuss the Top 10 Industrial Spark Plugs you should know about. Each plug has unique characteristics that suit different needs. Your choice can directly affect the durability and efficiency of your equipment. Let’s dive into the details.

Industrial spark plugs play a crucial role in various heavy-duty applications. These components ignite fuel in engines, ensuring optimal performance. Their effectiveness can significantly impact productivity in sectors like construction, agriculture, and manufacturing. A recent industry report highlights that spark plugs can improve engine efficiency by up to 15%. This is vital in an era where fuel costs are a major concern for businesses.

The applications of industrial spark plugs extend beyond standard engines. They are integral to generators, compressors, and pumps. Specific designs cater to harsh environments, resisting extreme temperatures and vibrations. However, many companies overlook the importance of regular maintenance. Failure to replace worn spark plugs can lead to engine misfires. In turn, this results in reduced output and increased operational costs. Interestingly, data indicates that 25% of equipment failures are linked to ignition system issues.

Innovation is ongoing in spark plug technology. Recent advancements focus on materials that enhance durability and performance. However, it raises questions about costs versus benefits for businesses. Investing in the latest technology might not always yield immediate returns, creating uncertainty. The challenge lies in finding a balance between maintaining existing systems and adopting new solutions. This complexity highlights an essential need for continuous education and assessment in spark plug applications.

| Type | Material | Application | Heat Range | Lifespan (Hours) |

|---|---|---|---|---|

| Copper Core | Copper | Heavy Machinery | Standard | 400-500 |

| Iridium | Iridium | Generators | High | 1000-1200 |

| Platinum | Platinum | Construction | Medium | 800-1000 |

| Ceramic | Ceramic | Industrial Equipment | Low | 300-400 |

| Multi-ground | Copper/Steel | Marine Engines | Standard | 600-800 |

| Long Reach | Nickel | High-Performance Engines | High | 900-1100 |

| Shorty Plug | Brass | Compact Equipment | Medium | 500-700 |

| Racing Spark Plug | Platinum/Tungsten | Motorsport | Very High | 1500-2000 |

| Laser Iridium | Iridium | High-Efficiency Engines | Ultra High | 1200-1500 |

| Long Life | Special Alloy | Heavy Equipment | High | 1000-1300 |

When choosing industrial spark plugs, several key features are essential. A crucial aspect is the material and design. Spark plugs made from copper or iridium offer superior conductivity. These materials ensure efficient energy transfer, which can enhance engine performance. According to recent industry reports, using the right spark plug can improve engine efficiency by up to 15%.

Temperature range also matters significantly. Industrial engines often operate in harsh environments. Thus, spark plugs must withstand extreme temperatures. A spark plug that operates within the appropriate temperature range reduces the risk of pre-ignition and fouling. Data suggests that improper temperature specifications can lead to a 25% decrease in efficiency over time.

Finally, consider the spark plug's gap. The gap affects ignition and combustion. An incorrect gap may result in misfires or incomplete combustion. The industry standard recommends frequent gap checks. Some studies indicate that a 1 mm change in gap can lead to a 10% decline in performance. Ensuring your spark plug is correctly gapped can be the difference between optimal performance and costly repairs.

When examining industrial spark plugs, it’s clear that various brands stand out. Each brand offers something unique. Some focus on durability while others emphasize efficiency. Finding the right spark plug can truly make a difference for industrial engines.

Consider the design and materials used. Certain brands focus on high heat resistance. Others may prioritize a longer lifespan. Innovations in insulation can lead to improved performance. However, not every brand excels in all areas. Some may sacrifice durability for a more affordable option.

It’s essential to evaluate specific needs. Different applications require different types of spark plugs. Some brands might not be suitable for heavy machinery. Pay attention to user reviews and feedback. It’s also wise to reflect on past experiences with spark plugs. The right choice impacts fuel efficiency and engine reliability.

When it comes to industrial spark plugs, performance varies significantly among different types. A comparative analysis revealed that copper spark plugs tend to have lower thermal conductivity but provide better ignition performance in lower-temperature environments. Industry data indicates that they offer an average lifespan of 20,000 miles. However, they can struggle in high-performance settings, leading to potential misfire issues.

In contrast, iridium spark plugs excel in longevity and efficiency. Studies show their lifespan can reach up to 100,000 miles. They operate well under high stress, making them a popular choice for heavy-duty applications. But their cost can be a barrier. Users often report that installation can be tricky due to their unique design. This can lead to installation errors, which may affect overall engine performance.

Additionally, platinum spark plugs offer a balanced option. They provide a compromise between cost and durability, with an average lifespan of 60,000 miles. However, their performance may not match that of higher-end iridium plugs. This inconsistency encourages users to weigh their specific needs against potential drawbacks in reliability and performance. The ongoing debate about optimal spark plug choice reflects broader challenges in the industry, highlighting the need for careful consideration of application requirements.

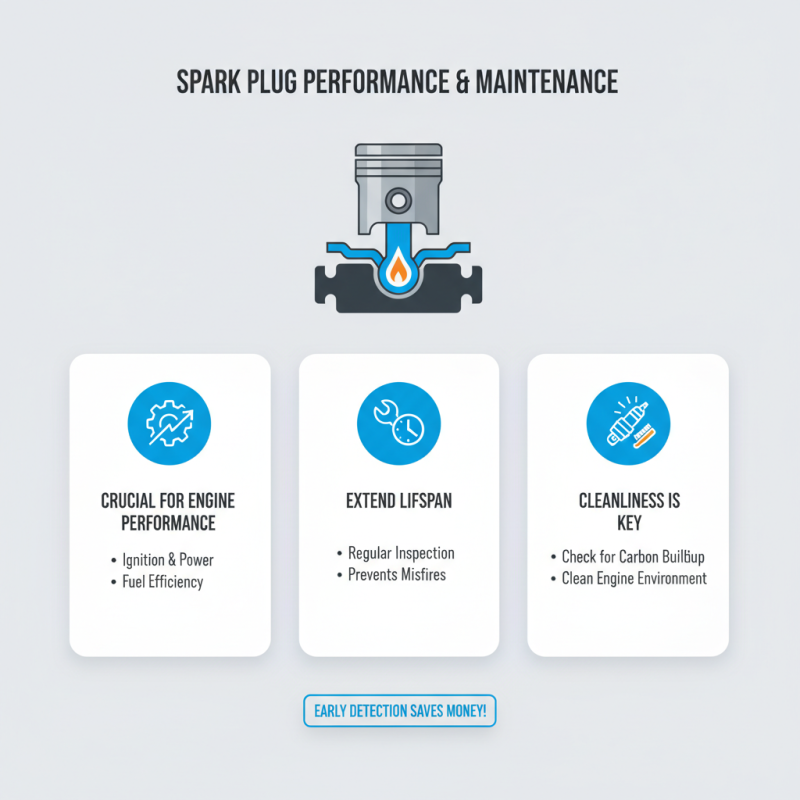

Spark plugs play a crucial role in engine performance. Regular maintenance can significantly extend their lifespan. One major aspect is cleanliness. Inspecting spark plugs for carbon buildup helps in identifying potential issues early. Maintaining a clean engine environment also prevents contaminants from affecting spark plug efficiency.

Another important tip is to check the gap. The gap between the electrodes can change over time. Using a feeler gauge, measure the distance to ensure proper spark generation. A too-wide or too-narrow gap can lead to misfires. Adjusting it can improve engine performance.

Temperature is another factor that affects spark plugs. Extreme heat can cause wear, while excessive cold can lead to fouling. Monitoring engine temperature ensures that spark plugs operate within the optimal range. If you notice unusual readings, consider inspecting the cooling system. By following these tips, you can help maintain your spark plugs for better engine performance.