When it comes to ensuring optimal performance and efficiency in industrial machinery, the choice of components plays a critical role. One such essential component is the Industrial Spark Plug, which serves as a vital link in the ignition process, igniting the air-fuel mixture within combustion engines. The right industrial spark plugs not only enhance engine performance but also contribute to fuel efficiency and reduce emissions, making them integral to sustainable operations in various industries.

In this guide, we will explore the ten best industrial spark plugs that stand out for their reliability and effectiveness. Our selection criteria focus on factors such as durability, heat range, and ignitability, as these attributes directly impact machinery performance in demanding environments. By understanding these key features of industrial spark plugs, businesses can make informed decisions that lead to improved operational efficiency and reduced maintenance costs, thereby maximizing the lifespan of their equipment.

Industrial spark plugs play a pivotal role in enhancing the performance and efficiency of various combustion engines used in manufacturing and power generation. Designed to withstand extreme temperatures and harsh conditions, these spark plugs ensure optimal ignition, which is critical for engine efficiency. According to a report by the International Energy Agency (IEA), nearly 70% of industrial machinery relies on effective ignition systems to maintain productivity. This highlights the significant impact that high-quality spark plugs can have on operational efficiency.

The importance of industrial spark plugs extends beyond just ignition; they are integral to reducing emissions and improving fuel economy. Recent studies indicate that using advanced spark plug technologies can lead to efficiency improvements of up to 15% in some applications. Moreover, the reliability of these components significantly influences the overall maintenance costs of industrial machinery.

A report from the Society of Automotive Engineers (SAE) showed that equipment downtime due to ignition system failures can result in substantial financial losses, emphasizing the need for durable and reliable spark plugs in the industrial sector. By ensuring optimal performance through quality spark plugs, industries can not only enhance productivity but also contribute to sustainable practices by minimizing their carbon footprint.

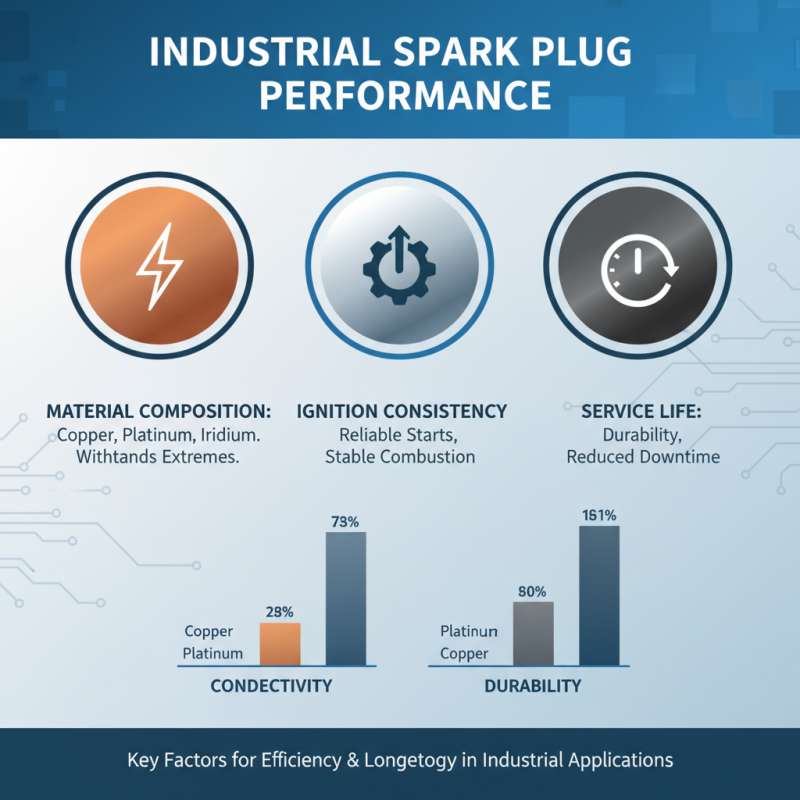

When it comes to industrial applications, the performance and efficiency of spark plugs are paramount. Several key factors influence their effectiveness. One of the most critical is the material composition. High-quality materials can withstand extreme temperatures and pressures, ensuring consistent ignition and longer service life. Copper and platinum plugs are often favored for their conductivity, while iridium is recognized for its durability, making it an ideal choice for high-performance applications.

Another significant factor is the spark plug's design, particularly its electrode configuration and gap. A properly calibrated gap allows for optimal spark efficiency, promoting better fuel combustion. Additionally, the shape and size of the electrode can influence heat dissipation. A design that facilitates effective heat transfer helps maintain an ideal operating temperature, preventing pre-ignition or misfire issues.

Tips for selecting the right spark plugs include regularly checking the manufacturer’s specifications for your industrial equipment. Consider the specific operating conditions, as extreme environments may necessitate specialized spark plugs. Finally, ensuring correct installation can greatly enhance spark plug performance; improper fitting can lead to diminished efficiency and premature wear. Prioritizing these factors can lead to significant improvements in operational performance and fuel efficiency.

When selecting industrial spark plugs, it is crucial to consider their features and specifications to ensure optimal performance and efficiency. Key elements to review include material composition, heat range, and electrode design. High-quality spark plugs often utilize materials such as iridium or platinum, which enhance durability and longevity, allowing them to withstand extreme conditions typically found in industrial settings.

A proper heat range is vital as it must match the engine's operating temperature to prevent misfiring or engine damage.

Another significant specification is the type of insulator and electrode configuration. A larger center electrode can improve ignition efficiency, while a solid insulator prevents fouling and increases operational reliability. Additionally, the gap between the electrodes should be adjustable or designed for specific applications to optimize spark intensity.

Ultimately, selecting the right industrial spark plugs based on these features can lead to better fuel efficiency, reduced emissions, and minimized maintenance needs.

When it comes to industrial applications, selecting the right spark plug is critical for optimizing performance and efficiency. Different types of spark plugs are designed to meet the unique demands of various industrial machinery, from generators to heavy equipment engines. For instance, high-temperature environments may require spark plugs that are resistant to wear and can withstand excessive heat, while applications involving frequent start-stop cycles benefit from plugs that ensure reliable ignition under varying conditions.

A comparative analysis of spark plugs can reveal variations in design and performance characteristics, helping users choose the most appropriate option for their specific needs. Factors such as electrode material, gap design, and insulator construction play significant roles in the efficiency of spark plugs. Some may incorporate advanced technologies to enhance ignition reliability and reduce emissions, while others focus on longevity and maintenance intervals. Understanding these differences enables businesses to make informed decisions, ultimately improving productivity and reducing operational costs across their industrial applications.

| Spark Plug Type | Application | Material | Thermal Range | Performance Rating |

|---|---|---|---|---|

| Copper Core | General Industrial | Copper | Heat Range 5 | 7/10 |

| Iridium | High Efficiency Engines | Iridium | Heat Range 6 | 9/10 |

| Platinum | Heavy Machinery | Platinum | Heat Range 7 | 8/10 |

| Nickel Alloy | Gasoline Engines | Nickel Alloy | Heat Range 4 | 6/10 |

| Multi-Ground Electrode | Industrial Machinery | Copper + Nickel | Heat Range 6 | 8/10 |

| Long Reach | Overhead Valve Engines | Steel | Heat Range 8 | 7/10 |

| Low-Emission | Environmental Applications | Copper | Heat Range 7 | 9/10 |

| Short Reach | Compact Engines | Nickel | Heat Range 5 | 6/10 |

| High-Performance | Racing | Iridium | Heat Range 10 | 10/10 |

| Resistor Type | Electronics | Copper Alloy | Heat Range 5 | 8/10 |

Maintaining industrial spark plugs is crucial for ensuring optimal performance and longevity. Regular inspections and

timely replacements can prevent potential issues that may arise due to wear and tear. It's important to monitor the spark plug's condition frequently, as

dirty or worn plugs can lead to decreased efficiency and increased fuel consumption. One effective way to maintain

spark plugs is to keep them clean. Regularly remove carbon deposits and other buildup by using an appropriate cleaning solution or a wire brush designed for this purpose.

Another key aspect of extending the life of spark plugs is proper installation. Ensure that the spark plugs are installed with

the correct torque as per the manufacturer's specifications. Over-tightening can lead to damage, while under-tightening can cause misfires and operational instability.

Additionally, maintaining the right gap between the electrodes is essential for optimal ignition performance. Using a reliable gap gauge during installation can help achieve

the desired spacing and improve overall efficiency.

Lastly, regular monitoring of the surrounding engine components can also enhance the lifespan of spark plugs. Check ignition timing, fuel quality, and overall engine health,

as issues in these areas can generate excessive heat or erratic performance that negatively impacts spark plugs. By following these maintenance tips, you can enhance the

efficiency of industrial spark plugs and ensure they perform at their best for longer periods.